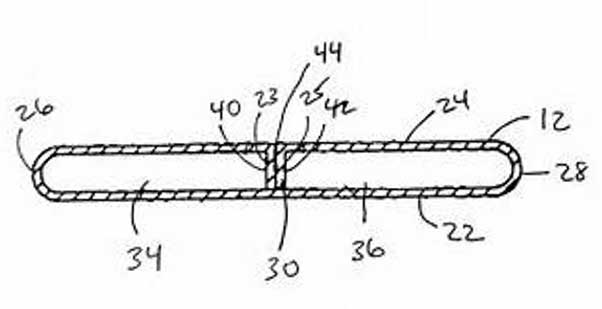

ALUMATECTMB TUBE Flux is used in the manufacture of folded tubes. An internal line of flux is used on the clad surface to facilitate the flow of the brazing material on the surfaces.

| AlumatecTM | Active Range | Process Application | Process | Uv Version | Viscosity | Flux Content |

|---|---|---|---|---|---|---|

| Standard | 564℃ - 572℃ | Auto Dispense | Folded Tube | Available | 500-75000cP | 10-70% |

| Standard Cesium | 558℃ - 568℃ | Auto Dispense | Folded Tube | Available | 500-75000cP | 10-70% |

| Delta Flux | 564℃ - 572℃ | Auto Dispense | Folded Tube | Available | 500-75000cP | 10-70% |

| Delta Flux Cesium | 558℃ - 568℃ | Auto Dispense | Folded Tube | Available | 500-75000cP | 10-70% |

Flux Paste 10kg 20kg 25kg or 20 lb. 40 lb. 50 lb.Plastic Containers